We Make Our Own Potassium Carbonate

Curious how we create one of the key science ingredients for our product development? Here’s a peek into our approach

Preparing the Solution

Potassium hydroxide flakes (KOH) are weighed and dissolved in distilled water, with quantities adapted for each batch size. The solution is mixed until fully dissolved.

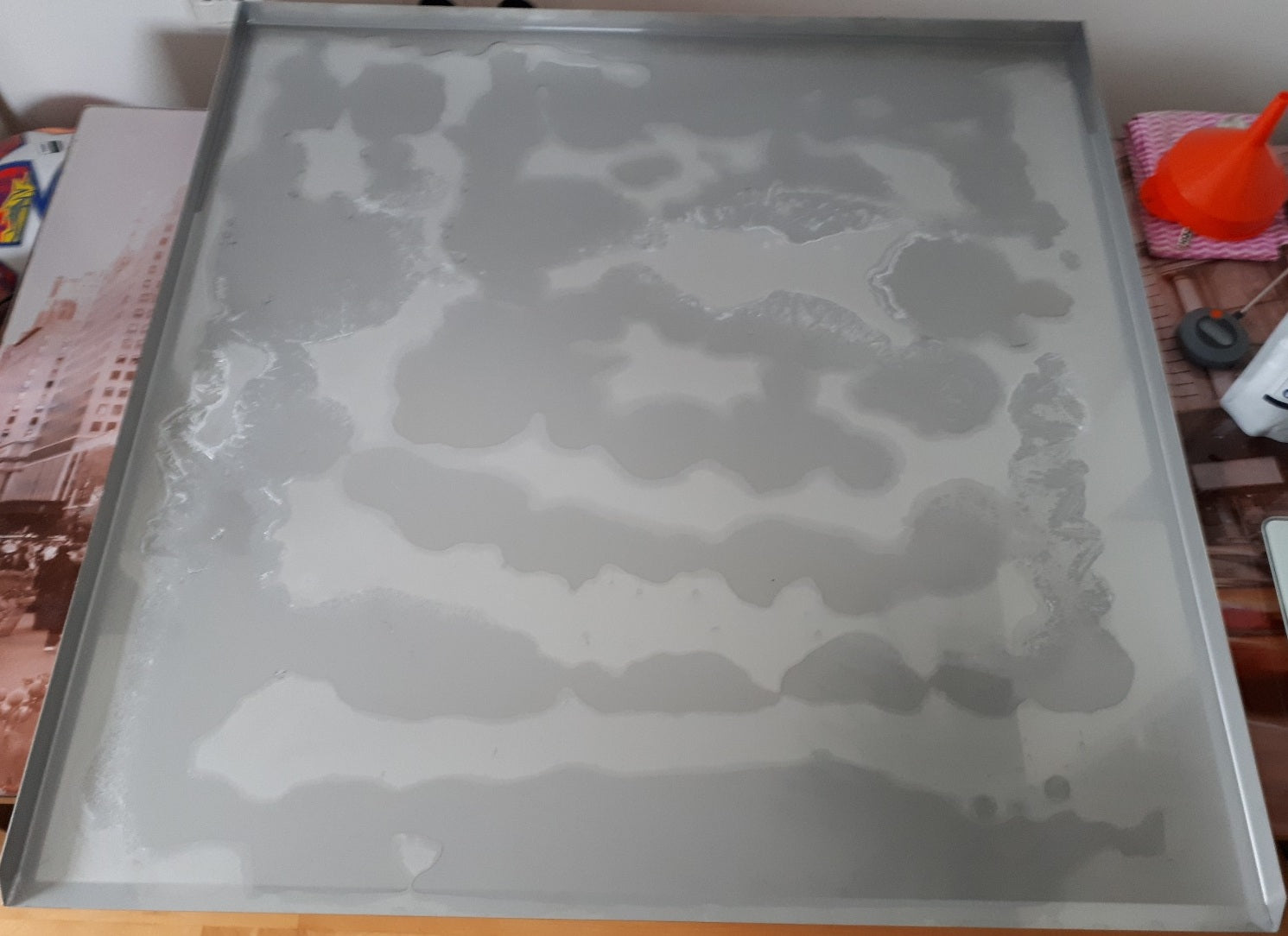

Pouring & Room Setup

The solution is poured onto stainless steel trays, one or multiple depending on volume needed. The trays are left to react with atmospheric CO₂ at the day's natural room temperature and humidity.

Carbonation & Harvesting

As the solution sits exposed to the air, it slowly absorbs CO₂ and begins to crystallize. We watch for the first signs of crystallization, then decide just when to collect the material for optimal quality. Sometimes it’s 10 hours, sometimes a bit longer, each batch finds its own rhythm.

Combining, Checking & Storing

When harvesting, we collect all trays’ yields and bring different batches together. Every combined batch is titrated to confirm the concentration meets our standards.

Before final storage, each batch passes through a fine food-grade filter to ensure purity, and is sealed in airtight containers. The solution is now ready to be used in our soap recipes!