Wir stellen unsere eigenes Kaliumcarbonat her.

Bist Du neugierig, wie wir einen der Hauptbestandteile unserer Naturseifen herstellen? Hier findest Du einen kleinen Einblick in unsere Vorgehensweise.

Auf die Plätze, fertig, los

Zubereitung der Lösung

Wir wiegen Kaliumhydroxidflocken ab und lösen sie in destilliertem Wasser auf, wobei die Menge an die jeweilige Chargengröße angepasst wird. Die Lösung wird gerührt, bis sich das Kaliumhydroxid vollständig aufgelöst hat.

Hier geschieht die Magie.

CO₂ aus der Luft abscheiden

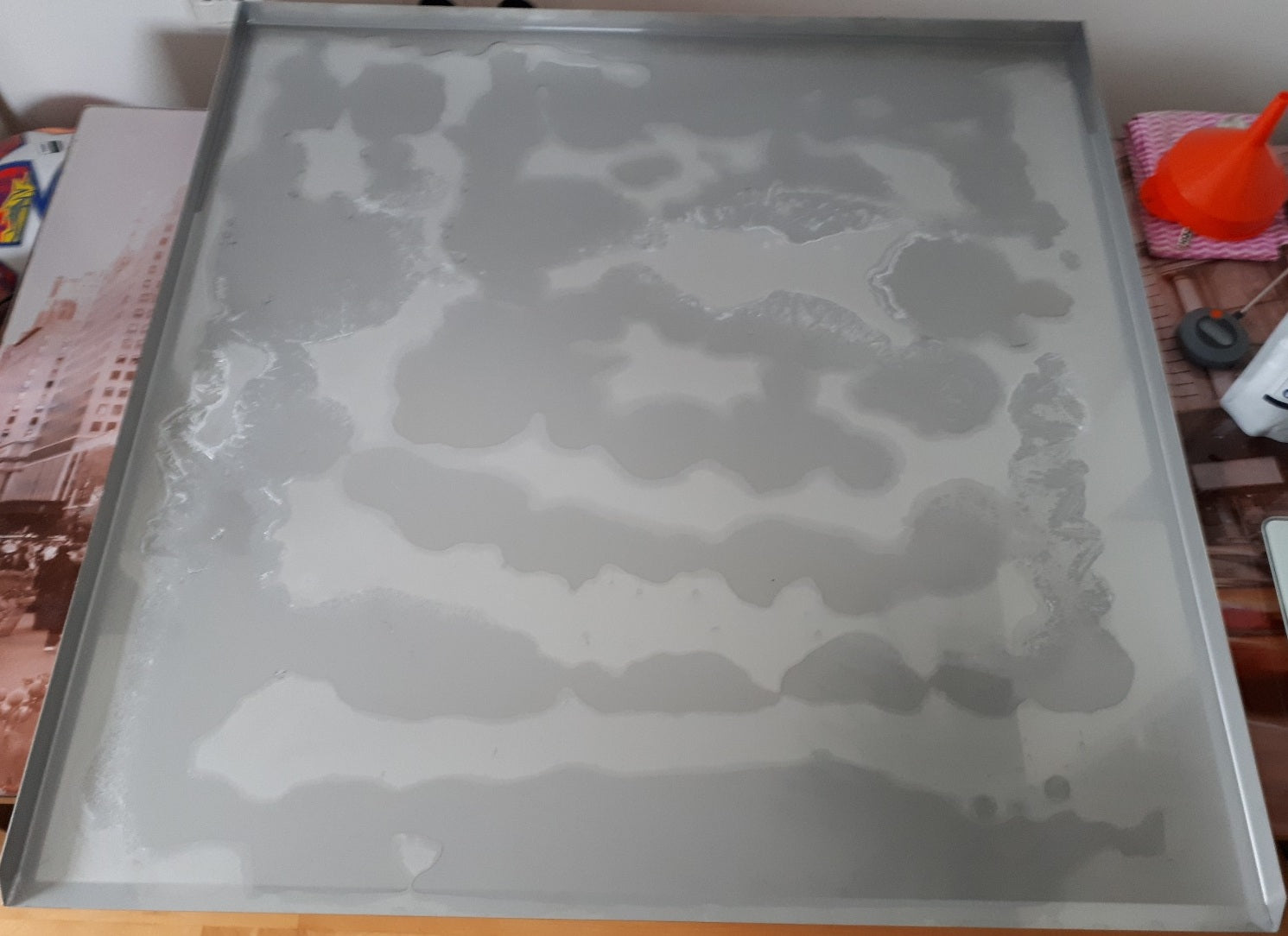

Die Lösung wird in Tablettschalen gegossen, je nach benötigtem Volumen auf eine oder mehrere. Die Lösung in den Schalen reagiert dann bei normaler Raumtemperatur und Luftfeuchtigkeit mit dem CO₂ der Umgebungsluft.

Luft und Zeit tun ihre Arbeit

Die Ernte einfahren

Während die Lösung der Luft ausgesetzt ist, nimmt sie langsam CO₂ auf und beginnt zu kristallisieren. Wir beobachten die ersten Anzeichen der Kristallisation und entscheiden dann, wann wir das Material für eine optimale Qualität ernten. Manchmal dauert es 20 Stunden, manchmal etwas länger; jede Charge entwickelt ihren eigenen Rhythmus.

Endgültige Textur

Salzgewinnung

Das geerntete Salz wird in verschlossenen Behältern gelagert und anschließend mikrofiltriert, um Partikel zu entfernen. Nun kann es in unserer CO₂-bindenden Naturseifenrezeptur verwendet werden und sorgt für besonders guten Schaum.